Glossary

We aim to communicate in a straightforward way avoiding using jargon which is unfamiliar to our clients

For those who would like to learn some of the more standard print and packaging terminology we have provided a glossary below.

Glossary Index

C

Canvas

Canvas is an extremely heavy-duty plain-woven fabric used for making a whole range of products including Canvas Bags.

Modern canvas is usually made of cotton or linen, although historically it was made from hemp. It differs from other heavy cotton fabrics, such as denim, in being plain weave rather than twill weave. Canvas comes in two basic types - plain and duck. The threads in duck canvas are more tightly woven. The term duck comes from the Dutch word for cloth, doek.

The word canvas is derived from the 13th century Anglo-French canevaz and the Old French canevas. Both may be derivatives of the Vulgar Latin cannapaceus for "made of hemp," originating from the Greek word for cannabis!

Canvas bags from Print and Packaging are made from 10oz natural unbleached canvas. With transfer printing it is possible to achieve photo quality printing onto canvas bags.

Cotton

Cotton is a soft, fluffy staple fibre that grows in a boll, or protective capsule, around the seeds of cotton plants of the genus Gossypium. The fibre is almost pure cellulose. The botanical purpose of cotton fibre is to aid in seed dispersal.

The plant is a shrub native to tropical and subtropical regions around the world, including the Americas, Africa, and India. The greatest diversity of wild cotton species is found in Mexico, followed by Australia and Africa. Cotton was independently domesticated in the Old and New Worlds.

The fibre is most often spun into yarn or thread and used to make a soft, breathable textile. The use of cotton for fabric is known to date to prehistoric times; fragments of cotton fabric dated from 5000 BC have been excavated in Mexico and Pakistan. Although cultivated since antiquity, it was the invention of the cotton gin that so lowered the cost of production and led to its widespread use, and it is the most widely used natural fibre cloth in clothing today.

Current estimates for world production are about 25 million tonnes annually, accounting for 2.5% of the world's arable land. China is the world's largest producer of cotton, but most of this is used domestically. The United States has been the largest exporter for many years.

Cotton bags from Print and Packaging are tactile, natural and 100% recyclable. They are a popular choice for businesses and organisations looking for a more environmentally responsible packaging solution.

Printed Cotton Bags from Print and Packaging - To see our range of Cotton Bags click here.

Counter Bags

These flat paper bags are highly versatile, used by a number of businesses such as card shops, gift shops, bakers and sandwich bars. As these bags are printed from reels of paper, it is possible to print on the entire surface of the bag giving maximum brand exposure. Counter Bags are made from Kraft paper which is 100% recyclable and compostable.

Printed Counter bags from Print and Packaging - To see our range of Counter Bags click here.

D

Display Packaging

Display Packaging increases brand awareness and builds brand loyalty by reaching the target audience very effectively.

Point-of-sale (POS) marketing is one of the most successful and widely-used forms of marketing communication. POS marketing often produces great results in the impulse-buy category. Attractive, well organized, strategically placed products get buyers' attention and make them aware of your product. This converts observers into long-term users.

Display Packaging from Print and Packaging - To view our range of Display Packaging click here.

Duffle Bag

Duffle style carrier bags are light versatile and popular items. These bags are suitable for a variety of purposes for all age groups.

This style of bag is very popular with the younger market common in all types of sports and clothing shops. Custom printed duffle bags are generally supplied in one size, however bespoke sizes can be produced on request. The standard duffle bag is fitted with a polypropylene rope handle which is threaded through a seam at the top and secured at the bottom with a metal eyelet, making this style of carrier bag very robust.

Duffle style carrier bags from Print and Packaging - To see our range of printed duffle bags click here.

E

Embossing

Embossing is a print finishing process (after printing). A die is made from the design, under several tons of pressure, the embossing die is forced onto the paper and the impression of the brass or magnesium die is left in relief on the paper.

For example, a logo or text might be highlighted by embossing. Embossing is also effective when used in non-printed areas as a subtle means of enhancing the printed job.

F

Flat Pack Folding Cartons

Folding cartons are ideal for point of sale displays or individual packaging for almost all market sectors. A folding carton is fabricated from paperboard. The paperboard is printed, die-cut and scored. Cartons are transported and stored flat, and erected at the point of filling. These are used to package a wide range of goods, intended either for one-time (non-resealable) use or as a storage box for the remaining goods. Cartons can be die cut to individual specifications with open or widowed apertures.

Flat pack folding cartons from Print and Packaging - To see a range our flat Pack folding cartons click here.

Flexiloop

The Flexiloop carrier bag has become popular with supermarkets around the UK where they are often branded as Bags for Life.

Flexiloop carrier bags are manufactured with a reinforced handle made from thick polythene which is welded to the inside of the bag forming the 'flexi loop'. The advantage of flexiloop Handle carrier bag is it allows for the full volume to be used without tearing. They are practical, comfortable on the hands and look very attractive.

Flexiloop carrier bags from Print and Packaging - To see our range of flexiloop carrier bags click here.

Flexographic Printing

Flexographic printing or flexography, is a printing process which utilises a flexible relief plate.

Flexography is the fastest growing conventional printing process, especially in packaging such as corrugated containers and flexible films. It has also made significant advances in publication printing, particularly newspapers. Because the quality of flexo printing has improved so much, it is now used extensively for process colour printing, as well as spot colour, on a wide variety of materials.

It is used extensively for printing tags and labels, many in full process colour. Flexography was originally called aniline printing because of the aniline dye inks that were originally used in the process.

The aniline dyes were made from coal tar and were banned for use in food packaging by the FDA because of their toxicity.

Flexography is like letterpress in that both print from a raised image surface. Flexo plates, whether molded from rubber or imaged from photopolymer, are generally made from flexible materials. Flexo inks generally are low viscosity, highly fluid and quick drying, although there is a trend toward higher viscosity inks. The inks are made from a dispersion of resins, solvents, colour and additives, which are either organic or aqueous based.

Essentially, flexographic printing is a modern version of letterpress, widely used for printing on the non-porous materials used in various types of food packaging. Flexographic printing is also well suited for printing large areas of solid color.

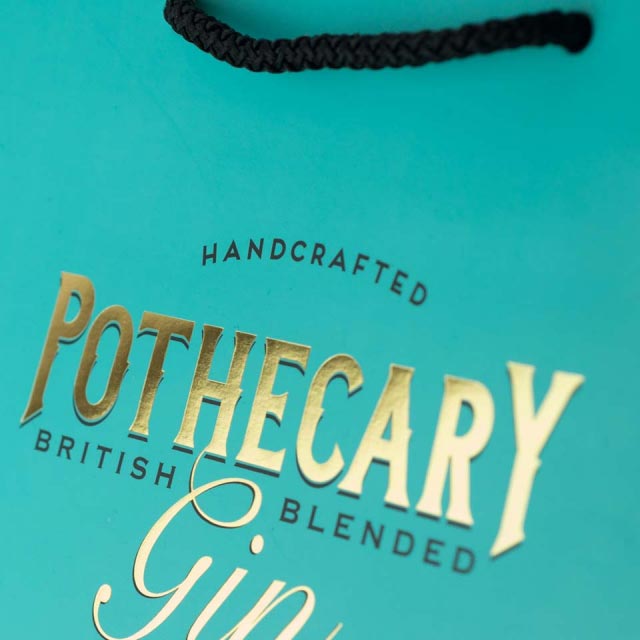

Foil Blocking

Foil Blocking uses metal foil which is applied to create shiny metal foil effects on paper. A die is made from the design, the design is then impressed onto the paper or board by means of a coloured metal foil.

Foil Blocking is mainly used as a special effect to enhance the overall look and quality of a print job. Foil Blocking is a printing process which is always done after the initial print element of the job but before final finishing.

G

Gloss Lamination

Gloss lamination adds a high silk sheen finish and forms a protective coating over the print.

Gloss lamination is a print finishing process, meaning it takes place after the initial printing stage. Lamination is plastic film in various finishes which is applied to the entire printed surface to create either a matte or gloss effect.

Gloss Spot UV

Ultra Violet (UV) Varnishing is a printing process used to enhance many kinds of print job with a gloss or matte finish.

Gloss Spot UV is a print finishing process (after printing). In Gloss Spot UV the varnish is applied to specific areas of a printed page such as text or pictures (not all over). Gloss Spot UV is a Screen Printing Process; from the supplied artwork a Silk Screen is made and the varnish applied to the desired areas using the screen. Spot UV Varnishing works particularly well on printed material that has already been Matte Laminated. Gloss Spot UV is not suitable for fine detail, such as small text.

Glossary

We aim to communicate in a straight forward way avoiding using jargon that’s unfamiliar to our clients. For those that would like to learn some of the more standard print and packaging terminology we’ve provided a glossary below.

J

Jute

Jute is a natural material and is grown in Bengal India. It is one of the cheapest natural fibres, second only to cotton.

Jute is a long, soft, shiny vegetable fibre that can be spun into coarse, strong threads. It is produced from plants in the genus Corchorus, which has been classified in the family Tiliaceae, or more recently in Malvaceae. However, it has been reclassified within the family Sparrmanniaceae.

Jute is one of the most affordable natural fibres and is second only to cotton in amount produced and variety of uses of vegetable fibres. Jute fibres are composed primarily of the plant materials cellulose (major component of plant fibre) and lignin (major components of wood fibre). It is thus a ligno-cellulosic fibre that is partially a textile fibre and partially wood. It falls into the bast fibre category (fibre collected from bast or skin of the plant) along with kenaf, industrial hemp, flax (linen), ramie, etc. The industrial term for jute fibre is raw jute. The fibres are off-white to brown, and 1-4 metres (3-12 feet) long.

Jute is also known as hessian and is popularly known as burlap in North America. Jute fibre is one of the strongest natural fibres and was often used to make rope before being exported to the UK to be manufactured into sacks and now carrier bags. Increasing popularity of the jute bag is due of the bag's rustic appearance. The jute bags we supply are available with a soft, padded loop handle or woven cotton flat tape handles.

Jute bag printing from Print and Packaging - To see our range of Jute Bags click here.

K

Kraft Flat Tape Handles

The benefits of kraft paper bags are that they are a strong and reusable, as well as recyclable and compostable. Many takeaways, delicatessens and sandwich shops use flat tape handle paper bags as they are strong, hygienic and attractive.

Flat tape handle kraft paper carrier bags from Print and Packaging - To see our range of flat tape handle kraft paper bags click here.

Kraft Paper

Kraft Paper is environmentally friendly, made with paper from fully sustainable FSC certified sources. Kraft paper is produced from chemical pulp produced in the kraft process.

Pulp produced by the kraft process is stronger than that made by other pulping processes; acidic sulfite processes degrade cellulose more, leading to weaker fibres, and mechanical pulping processes leave most of the lignin with the fibres, whereas kraft pulping removes most of the lignin present originally in the wood. Low lignin is important to the resulting strength of the paper as the hydrophobic nature of lignin interferes with the formation of the hydrogen bonds between cellulose (and hemicellulose) in the fibres.

Kraft pulp is darker than other wood pulps, but it can be bleached to make very white pulp. Fully bleached kraft pulp is used to make high quality paper where strength and whiteness is important. Kraft paper is 100% recyclable and compostable.

Kraft Twisted Handles

The benefits of Kraft paper bags are that they are a strong and reusable, as well as recyclable and compostable. Twisted paper handles are comfortable to hold, and have a quality appeal.

Kraft Twisted Handle bags from Print and Packaging - To see our range of Kraft Twisted Handle Bags click here.

L

Laminated Paper

Lamination is plastic film in various finishes which is applied to the entire printed surface to create either a matte or gloss effect. Lamination is a print finishing process, meaning it takes place after printing. Our laminated paper bags are handmade. As such it is possible to print on the inside of the bag and base card.

Litho or screen printed onto silk or gloss coated board, which can then be either gloss or matte laminated, producing a durable finish. Laminate paper bags are strong, and can be made out of recycled paper if required, there is also the option of using bio-degradable lamination.

Laminated Rope Handle Bags from Print and Packaging - To see our range of Laminated Rope Handle Bags click here.

Lithographic Printing

Lithographic Printing (also called Offset Lithography) has remained the industry standard printing process due to its advantages in quality, efficiency and the high volume runs achievable.

Lithography is a form of printing in which the image to be printed is rendered on a flat surface. The flow of ink is controlled by coatings on the printing plate; printing areas are treated to retain ink while the non-image areas are made ink-repellent.

Lithographic Printing is by far the most popular form of printing accounting for around 40% of all printed output worldwide. Lithographic printing is usually the most cost-effective solution for long runs, producing high quality printing and extremely accurate colour reproduction.

M

Mailing Bags

Printed mailing bags are used as promotional accessories for companies posting items to their client or customer base. Mailing bags are lightweight and durable and come in a variety of sizes. They are also supplied with a hot-melt glue seal, guaranteeing content security.

Printed Mailing Bags from Print and Packaging - To see our range of Mailing Bags click here.

Matte Lamination

Matte lamination is a print finishing process, meaning it takes place after the initial printing stage.

Lamination is plastic film in various finishes which is applied to the entire printed surface to create either a matte or gloss effect. Matte Lamination gives a subtle, tactile effect. Whilst forming a protective coating over the print it does not provide the same level of protection as gloss lamination and can be prone to scratching and fingerprints.

Matte Spot UV

Ultra Violet (UV) Varnishing is a printing process used to enhance many kinds of print job with a gloss or matte finish.

In matte spot UV, the varnish is applied to specific areas such as text or pictures.

Matte Spot UV is a print finishing process (applied after printing). Matte Spot UV is a Screen Printing Process, from the artwork a Silk Screen is made and the varnish applied to the desired areas using the screen. Spot UV Varnishing works particularly well on a cover that has already been matte laminated. Matte Spot UV is not suitable for fine detail, such as small text.

N

Non-Woven

Non-woven bags are constructed from 100% non-woven, soft textured polypropylene. The fabric is tear proof and water repellent. These bags are ideal for promotions, gifts, advertising and retail. Available from stock with reinforced long or short handles, cotton or polypropylene rope (eyelets available).

Non-Woven Carrier Bag Printing from Print and Packaging - To see our range of Non- Woven Carrier Bags click here.

O

Organic Cotton

Organic cotton is generally understood as cotton, from plants not genetically modified, that is certified to be grown without the use of any synthetic agricultural chemicals, such as fertilizers or pesticides.

Its production also promotes and enhances biodiversity and biological cycles. United States cotton plantations are required to enforce the National Organic Program (NOP). This institution determines the allowed practices for pest control, growing, fertilizing, and handling of organic crops. As of 2007, 265,517 bales of organic cotton were produced in 24 countries, and worldwide production was growing at a rate of more than 50% per year.

P

Patch Handle

The patch handle bag is our most popular style of plastic carrier. The handle is punched out of the polythene, making this bag comfortable to carry. Most commonly used in retail environment, patch handle carriers are a stylish and cost effective option for printed carrier bags.

Patch handle carrier bags from Print and Packaging - To see our range of patch handle carrier bags click here.

Pillow Packs

Pillow boxes are a convenient, elegant packaging option for small items. They store flat and easily pop into shape, with elliptical end closures and a curved, pillow shape.

These small cardboard boxes are perfect packaging for small gift items like jewellery, ties, cosmetics and soaps. A great solution for sending items by direct mail. Gift packaging is a great branding opportunity. Get your logo imprinted to make a lasting impression, add luxury to your product or sell them separately as an easy gift-wrapping solution.

Custom Pillow Pack Printing from Print and Packaging - Available in a wide range of sizes and print options, to find out more click here.

Printed Tissue Paper

Tissue paper is a great way to accent shopping bags, finish gift wrapping and wrap breakable items.

Some shops wrap delicate merchandise in folded or crumpled layers of tissue paper to protect it before placing it in bags or boxes for the purchaser.

Coloured wrapping tissue can be used for an assortment of visually creative purposes. For example, when wetted, the colour bleeds a watercolour-like layer of tissue paper that stays when you peel off the tissue paper. Tissue paper can be crumpled up to form objects, such as flowers.

For production tissue paper for wrapping is made by the machine glaze process. A slurry of fibre is placed on a forming wire where the water is allowed to drain away. The sheet is then pressed against a felt and pressed against a drying cylinder for the final drying step. The sheet is then pulled away from the dryer and wound up ready for further converting into wrapping paper.

Did you know? - Tissue paper was used by musicians in the early 1900s to play the comb, producing a sound similar to the kazoo. Jazz musician Red McKenzie was one of the best-known players.

Printed Tissue Paper from Print and Packaging - Available in a wide range of colour and print options, to find out more click here.

R

Ribbon

A ribbon is a thin band of material, typically cloth but also plastic or sometimes metal, used primarily as decorative binding and tying. Cloth ribbons are made of natural materials such as silk, cotton and jute and of synthetic materials such as polyester, nylon and polyproylene. Ribbon is used for innumerable useful, ornamental and symbolic purposes. Some popular major types of ribbon are Satin, Organza Sheers,Velvet and Grosgrain.

While satin and other sorts of ribbon have always been used in lingerie, the usage of ribbon in the garment industry, while subject to fashion trends, saw an upsurge in the mid to late 90's. This upsurge led to increased ribbon manufacturing as well as new and improved manufacturing techniques.

Pieces of ribbon are used as symbols of support or awareness for various social causes and are called "awareness ribbons".

Ribbons are used in some ceremonies, such as in a ribbon-cutting ceremony.

Ribbons also find use in gift-wrapping, symbolic reference to the opening of a new event etc.

Add a little elegance, fun, and flair to your gift wrapping or packaging. Used in combination with other branded packaging, printed ribbon can add a great finishing touch.

Print and Packaging offer a huge selection of classic and elegant ribbons. To help you find the perfect finishing touch for your product, click here.

Rigid Presentation Boxes

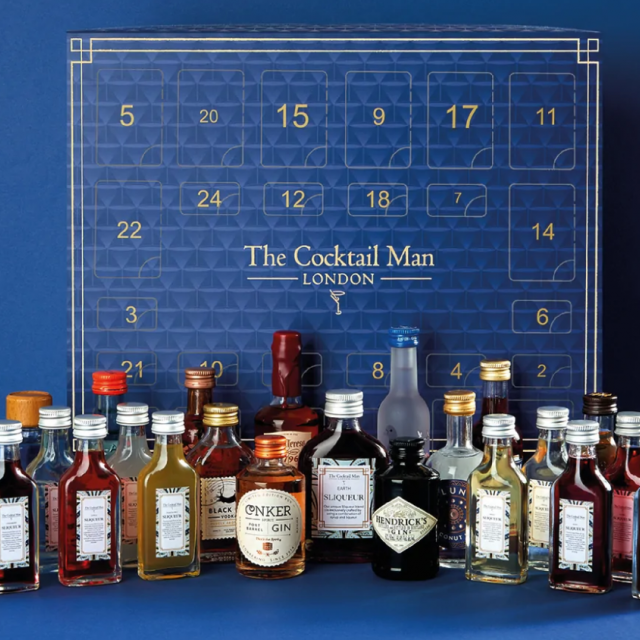

Rigid presentation boxes are at the high end of product packaging.

Constructed from stiff paperboard, permanently glued together with paper skins that can be printed or coloured. These boxes are assembled at the point of manufacture, These boxes provide structural strength and the ability to provide good protection for contents. Typically used for protecting high value items such as cosmetics, watches or smaller consumer electronics.

To see our range of rigid presentation boxes please click here.

S

Screen Printing

Screen printing is a stencil method of printmaking in which a design is imposed on a screen of silk or other fine mesh, with blank areas coated with an impermeable substance. A roller or squeegee is moved across the screen stencil and ink is forced through open areas of the mesh onto the printing surface.

Sleeves

Box sleeve printing and packaging allows you to impress consumers with a vibrant logo and even permits you to display your product through a content window.

If you want to draw immediate attention to your product, printed sleeves are a great way to gain a competitive sales edge and package your product conveniently.

Box sleeve printing from Print and Packaging - Custom-Printed Sleeves made bespoke and die cut to your requirements, for more information, click here.

T

Takeaway Bags

Specialist food bags manufactured using high density polythene for the food industry. This style of printed carrier bag is available with punched out handles, flexiloop handles, and tri-folded / flat tape handles. These bags are made to measure with a square base to hold food containers.

Takeaway Bags from from Print and Packaging - To see our range of Printed Takeaway Bags click here.

Tape

Adhesive tape is one of many varieties of backing materials coated with an adhesive. Several types of adhesives can be used.

Box-sealing tape, parcel tape or packing tape is a pressure-sensitive tape used for closing or sealing corrugated fibreboard boxes. It consists of a pressure-sensitive adhesive coated onto a backing material which is usually a polypropylene or polyester film which is oriented to have strength in both the long (machine) direction and the cross direction.

Most often, the tape is 48 mm (approx 2 inches) wide but it is also used in 72 mm (approx 3-inch) widths.

A variety of backing strengths and calipers as well as adhesive formulations are available. It is often transparent or tan (beige, buff, brown). Other colours and printing are sometimes available.

The tape can be applied manually with a stationery dispenser but is more often applied with a hand-held tape dispenser. This allows the user to more efficiently place the tape on the box, cut it off, and rub it down.

Automated machinery for application of tape to high-speed lines is also common.

Print and Packaging supply high quality vinyl tape, which can be custom-printed and personalised with your logo and company details.

To view our range of printed tape click here.

U

Unlaminated Paper

Suitable for litho, screen or transfer printing options, unlaminated paper is uncoated which means these bags are 100% recyclable. Our luxury unlaminated rope handle bags are handmade. As such it is possible to print on the inside of the bag and base card.

Unlaminated Rope Handle Bags from Print and Packaging - To see our range of Unlaminated Rope Handle Bags click here.

V

Varigauge

Varigauge Carrier Bags are a variation on the popular Patch Handle Carrier. As the name suggests, the gauge (thickness of film) increases from the bottom of the bag to top of the bag, providing additional strength around the handle area of the bag.

Varigauge Carrier Bags from Print and Packaging! To see our range of Varigauge Carrier Bags click here.

Vest

Common in supermarkets and general stores, the reason vest carrier bags are so popular is they are versatile and cheap. The bags are strong, durable and can be utilised for multiple purposes. These bags are a comfortable bag to carry and because they are manufactured with a long handles it is possible to carry multiple bags at a time.

W

Woven

Our Woven Carrier Bags are made from printed OPP film and woven polypropylene material, these robust carrier bags make ideal "bags for life". Woven Polypropylene Bags are available with matte or gloss lamination.

The OPP film is printed with your design and then bonded to the Woven PP material. The panels of the bag are then cut to size and stitched together to create the finished product.

Handles are usually made out of nylon webbing stitched to the top of the bag,

Woven Carrier Bags from Print and Packaging -To see our range of Woven Carrier Bags click here.