Packaging glossary

Aperture Handle:

Body of the bag has a punched out section to be used as a handle.

Art-Board:

Material that is slightly thicker than paper- has a smooth surface to create crisp print on.

Biodegradable:

Items that are Biodegradable have an additive built in them during the manufacturing process. This substance allows the plastic to break down quicker, by having the ability to be decomposed by living things or bacteria.

“Oxo-biodegradable” plastic can also be a great alternative to this – a more in depth explanation is listed further down this page.

Block Headed:

Bags are held together by heating the top header. Block headed bags are ideal where “easy- tear” is needed for quick packaging of goods. The head of the bags can be made with holes to fit a variety of display racking including euro-slots.

Bottom gusseted:

Added material to the bottom of the bag, creating more space and strength to its structure. Bottom gusseted carriers can normally stand up by themselves making them ideal for carrying food and drink.

Clear Film Window:

A transparent thin piece of polypropylene is inserted usually in the middle of an open-ended paper bag creating a “window”. This style is ideal for packaging baguettes, sandwiches and patisseries- as the food inside remains fresh and protected whilst still being visible.

Digital Printing:

A type of printing that does not need a printing plate made, as the artwork is sent directly to the printer. This is usually a faster way of having bespoke items made as there is minimal set up required. Ideal for start-up companies and/or smaller orders.

Die-cut:

Body of the bag has a punched out section to be used as a handle.

Flexi Loop:

“U” shaped handles attached to the main body of the bag. These handles can come in various colours and can be reinforced. Popular with fashion and clothing outlets.

Full Colour Print:

Uses the full spectrum of colours combined together in different ways to make up an image (it is also known as C.M.Y.K Print). Ideal for high definition/ photograph quality print work.

Gauge:

Unit used to describe the thickness of plastic. To convert this into micron, divide the gauge number by 4 for example: 500 gauge / 4 = 125 Micron. A list of grades are detailed below:

80 – 100 gauge: Very Thin (Ideal confectionary bags or dust covers etc.)

120-150 gauge: Thin (Ideal for confectionaries, dust covers, clothes and paperwork etc.)

180-200 gauge: Light/Medium (Ideal for carrying food items or household waste etc.)

250-350 gauge: Medium (Ideal for packaging warehouse, retail and industrial products etc.)

400-500 gauge: Medium/Thick (Ideal for items that are bulky or carrying weighty goods etc.)

600- 800 gauge: Thick (Ideal for products that have pointed edges, bulkier items and weighty goods etc.)

1000+ gauge: Very Thick (Ideal for times when ultimate strength is required, polythene sheeting in this thickness is used as damp proofing under concrete etc.)

GSM:

Grams per square metre is the unit used to describe the thickness of paper items.

HDPE/MDPE/LDPE:

HDPE- High Density Polythene- Economical/Cost-Friendly Plastic

MDPE- Medium Density Polythene

LDPE- Low Density Polythene- Higher Quality Plastic

Kraft:

Process used to make paper that is usually more durable and holds a higher strength than the average kind.

Litho Printing:

Ink is applied to a printing plate, which prints onto rollers or rubber blankets, from there it is then applied to the product. It is done this way to preserve the life of the metal plates and allow printing on any type of surface. Litho printing allows the use of a full range of colours to create high definition images at a faster rate than Screen Printing. This process is more suitable for larger orders and/or companies who have photographic artwork.

Low Noise:

Often used as a description for the adhesive used on tapes, meaning that there is a reduced amount of noise when tearing it. Ideal for busy or confined workplaces where sound should be kept to a minimum.

Micron/ Mu:

Unit used to measure the thickness of plastic.

See “Gauge” for a more in depth explanation.

Non- woven polypropylene:

Plastic fibres that are bonded together rather than “woven”. Ideal for those who wish to have cost-effective strong packaging for their products.

See “Woven Polypropylene” below.

Over Printing

Process of printing colours that layer on top of each other to create a special effect.

Oxo-Biodegradable Polythene bags

This is the most environmentally friendly option without losing the durability qualities of a standard plastic carrier. Oxo-Biodegradable bags have a unique material composition which allows it to degrade with prolonged exposure to air. These bags can also be recycled in a normal plastic waste stream.

Polypropylene:

A type of plastic that is versatile in many ways. Polypropylenes main properties is that can be made totally translucent and resistant to many chemicals. Polypropylene clear bags/film have a shinier appearance than standard polythene, making them ideal for displaying products and storing light-weight goods.

Polythene:

Is the most common plastic used in manufacturing. Polythene can be the ideal material for packaging heavier items and products that require reduced light exposure/ water resistance.

Reinforced Handle:

Handles that are made with added strength for carrying heavier items.

Glue patched: A strip of plastic is glued onto the handle. This provides additional strength when heavier items are placed inside.

Welded patched handle: A strip of plastics is welded onto the handle. This is ideal for when maximum strength is required.

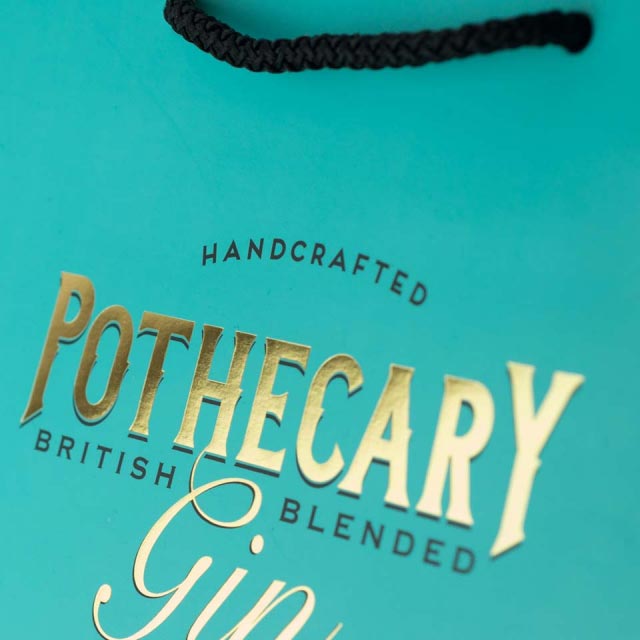

Screen Printing

A fine mesh stencil is stretched out across the product which allows ink to be pushed through to create the artwork. It is the ideal cost-effective method of printing for those with simple artwork on a larger scale and/or those who wish to have the same print repeatedly.

Side Gusset

Added material to each side of the bag, which opens up to allow more room for packaging items.

Spot Colour

A solid colour print, which is applied during a single run requiring its own printing plate to be made. Ideal for simple artwork designs on a larger scale.

Square-base

A flat base at the bottom of the bag that allows items to stand up in.

Varigauge

This primarily pertains to polythene carriers where the bag is thicker in material at the top (near the handle) than the bottom to give added strength to it.

Woven polypropylene

Plastic fibres that are woven together to create an extra strong but lightweight material. This allows woven polypropylene bags to be reusable and durable.